Nội dung

1. Customer Information

- Industry: Manufacturing plastic sheets for refrigerators through stamping and vacuum forming methods.

- Location: Bac Ninh

2. Current Context

A plastic sheet manufacturing company in Bac Ninh is facing several challenges in managing its finished goods inventory. Products need to be managed by lot or pallet, and when sold, they may be calculated by actual or theoretical weight. However, the lack of an efficient production management system has resulted in difficulties in controlling inventory and accurately calculating sales.

3. Challenges

3.1. Inventory Management by Primary Unit and Weight (kg)

The company needs to manage inventory by both primary unit and weight, but the current system fails to meet these requirements effectively, leading to inaccuracies during inventory checks and management.

3.2. Inventory Management by Lot or Pallet

Managing inventory by lot or pallet is not consistently implemented, making it difficult to track and manage stock levels, which increases the likelihood of errors.

3.3. Calculating Actual and Theoretical Weight for Sales

When selling products, the company needs to choose between actual and theoretical weight for pricing. This task is currently challenging because the system is not optimized to handle both weight calculation methods.

4. Proposed Solution: IFMS Production Management Software

To address these issues, the company decided to implement an IFMS software system with specialized features tailored to meet their needs:

4.1. Managing Units and Weight

Users can define the primary unit and conversion units directly on the Item screen. During stock entry/exit, inventory checks, and management, the system will display both quantity and weight information for each product lot. This ensures accuracy and consistency in inventory data management.

4.2. Lot and Pallet Management

Users can define finished goods to be managed by lot or pallet on the Item screen. For products managed by pallets (such as rolls), the system automatically splits the number of pallets and generates lot numbers based on production directives. This optimizes production and inventory management processes, minimizing errors and reducing manual intervention.

4.3. Weight Management in Sales

The system allows users to define finished goods to be sold by actual or theoretical weight. When production results are entered, the system automatically processes and records the appropriate weight. For products sold by actual weight, the system records the weight after weighing to ensure accuracy during sales.

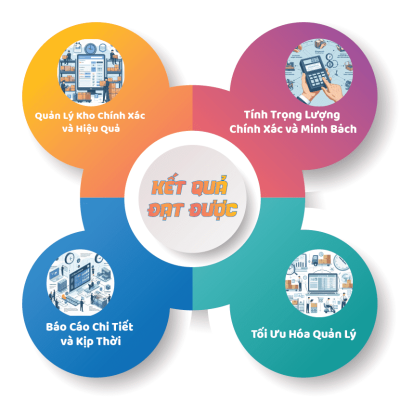

5. Achieved Results

5.1. Accurate and Efficient Inventory Management

The solution has enabled the company to manage inventory by lot or pallet accurately and efficiently. Real-time inventory updates provide the company with timely and precise stock information.

5.2. Accurate and Transparent Weight Calculation

The new system ensures precise calculations for both actual and theoretical weight, reducing errors and ensuring transparency in sales. This boosts customer trust and enhances sales performance.

5.3. Optimized Management

The system saves the management team time and effort in inventory checks, timekeeping, and inventory management. They can easily access information about stock levels, quantities, and product weights, enabling quick and effective decision-making.

5.4. Detailed and Timely Reporting

The system provides detailed reports on inventory status and operational performance, giving management a comprehensive overview for timely decision-making. This makes it easier for the company to evaluate and optimize its operations.

6. Conclusion

The implementation of the new warehouse management solution has brought significant benefits to the plastic sheet manufacturing company in Bac Ninh. The solution has not only optimized inventory management processes, saving time and effort , but also ensuring accuracy and transparency in weight management and sales. This not only enhances the company’s operational efficiency but also strengthens its competitiveness in the market, contributing to its sustainable growth.